Create CAD 2D Release V11 : training and workshop day for pattern technicians

In the new Crea Solution Headquarter took place the day dedicated to specialized technicians for updating and training about the software CAD 2D for pattern makeing Create™ V11.

The whole day was verticalized on the analysis of the new specific features for the creation and modification of patterns, rapid digitalization systems, and direct importers of proprietary formats (Lectra, Optitex, Gerber, Autodesk) that allow to import pattenrs created with other CAD without having to convert them to DXF, thus keeping all sewing information and internal entities such as notches, buttons and holes. For the apparell industry, the pattern making activity is speeded up through the multiple registry tools (quick deletion of names and entities, quickly rename the pieces, quickly copy the points, automatically assign the description of the piece and manage the history of the models, opening and saving sessions intermediate, with previous work recovery). The automotive industry instead exploits the potential of this CAD also for the production of leather seats, through the allocation of quality zones that will then be presented again in the automatic nesting on leather, as well as the biggest players in the furniture industry and salons, a sector that requires great flexibility and integration of processes, which have automated production processes thanks to integrations with Create ™ (2D CAD), Mind Cliché ™ (automatic nesting) and their CAM systems.

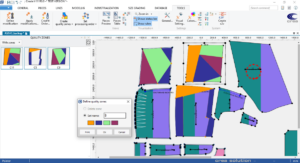

Quality Zones

✓ Assign the “quality” attribute to the internal lines

✓ Give a geometric definition of the regions of a piece through direct line design

✓ Define the part quality level through type assignment / code

✓ It also plans its management in the HPGL OUT module

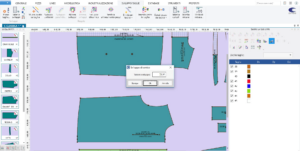

Direct importers of proprietary formats (alternative to DXF AAMA ASTM)

Direct importers speed up the work flow and the communication with outsourcing pattern makers, allowing pattern area to directly work with files in MDL, PDS… created with other CAD.

Particular attention was also given to the modules for the size grading, Exapander ™, digitalization of paper patterns through an optical pen, scanner or blackboard, Draw ™ and Survey ™, detection of the leather through artificial vision, IVS ™, verticalizations of the various versions of Create ™ for Clothing, Automotive, Furniture, Composite Materials and Small Leather Goods.

Dynamic Size Grading

The dynamic size grading is a tool that is drastically speeding up the design in the clothing industry as it allows an increase of grading on a point or on more points in a constant way, both in the X and Y boxes, and in the negative or positive sense. For example, to grading the side of a shirt by 1 cm, just enter the value in the grading box and all the points that I select will grade 1 cm, both positive and negative, on the entire side.

Defining Sections

It’s now possible to define the cutting direction of the pieces of the model, if a piece has a particular shape (with an acute angle for example) that if cut with the automatic cut could ruin the cut piece, the new command define sections I can instruct the automatic cut in the cut , defining the cutting direction so as to preserve the quality of the cut. With this command I also have the possibility of not cutting (in the case in which in the stretch of selvedge there is an embroidery or a lace) some traits, directly inserting this instruction in the HPGL file

Crea Overcut

It is finally possible to handle the circle cut on fabric precisely with this new feature. By clicking on a closed inner line on one of its points, the lines are automatically opened inside to give more accuracy to the inbound and outbound cutting blade.