- Single-Layer

Automatic Cutting - Artificial Vision

Cutting - Multi-layer

Automatic Cutting - Automatic

Leather Cutting

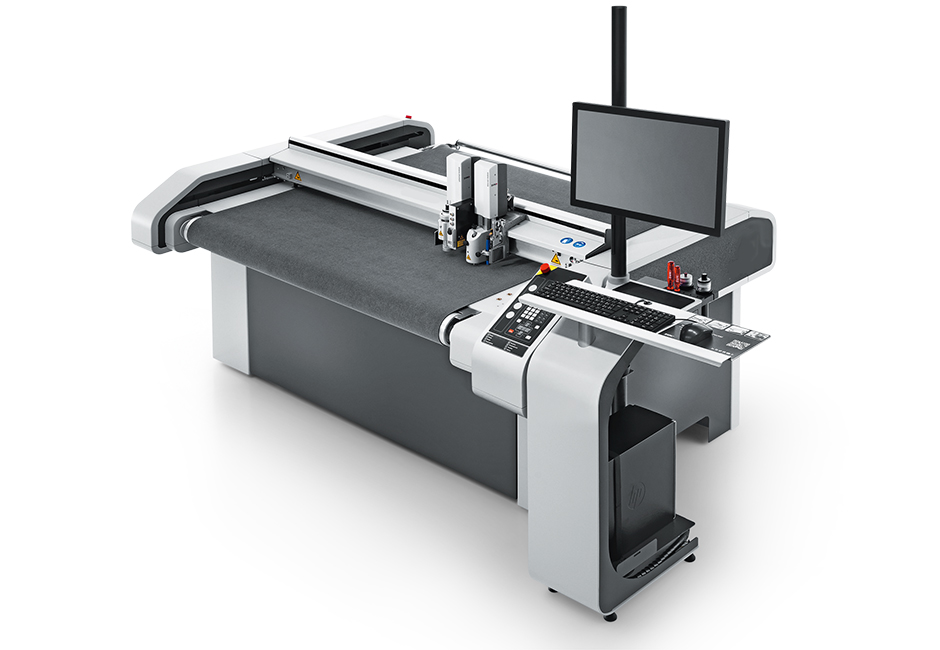

Maximum customization

for every cutting need

Crea Solution’s cutting system stands out for its modular structure, which allows each component to be configured according to your production requirements. With customizable tools and machine dimensions, it’s the ideal solution for those seeking a made-to-measure, precise, and versatile setup fully adaptable to every stage of the workflow.

Speed, efficiency, and uncompromised quality

Compact, fast, and designed to meet the highest safety and productivity standards, the Crea Solution system integrates responsive motors, smart sensors, and advanced cutting technology. The result is high-precision continuous processing that reduces production time and maximizes finished product quality.

Ergonomics and control for smooth production

Designed to simplify the operator’s tasks, the system offers an intuitive interface and ergonomic handling. The acrylic cutting surface features adjustable vacuum fixation to ensure optimal panel stability during the process. A user-friendly layout and smart material transport solutions contribute to a streamlined, efficient nesting and cutting process.

Direct reading of checkered and striped fabrics with fabric defect detection

IRIS continuously cuts checkered and striped fabrics even ultra-fine patterns or tone-on-tone designs while detecting fabric defects and dynamically repositioning the patterns in real-time during cutting, ensuring perfect pattern alignment in the finished garment.

- Perfect check matching between pattern parts

- Automatic parameterization via AI

- Fabric defect recognition

- Continuous cutting: IRIS cuts while reading the fabric

- Integrated with the Crea MTM/MTO platform

Artificial Vision and Automatic Cutting for Panels, Allovers, and Complex Graphics

Large panels, allover prints, complex graphics to reconstruct, printed panel sections on fabric, and ensuring seamless motif continuity in the finished garment these were the core challenges driving the latest IRIS innovation.

Garments with logos requiring reconstruction

IRIS performs continuous cutting of fabrics with logos, detecting distinct shapes and colors, small numbers or letters, and even tone-on-tone branding. It identifies defects and repositions the patterns in real-time during cutting to ensure flawless logo alignment in the final garment.

- Seamless continuity and logo reconstruction in the final garment

- AI-driven parameterization

- Continuous cutting: IRIS cuts while scanning the fabric

- Fully integrated with the Crea MTM/MTO platform

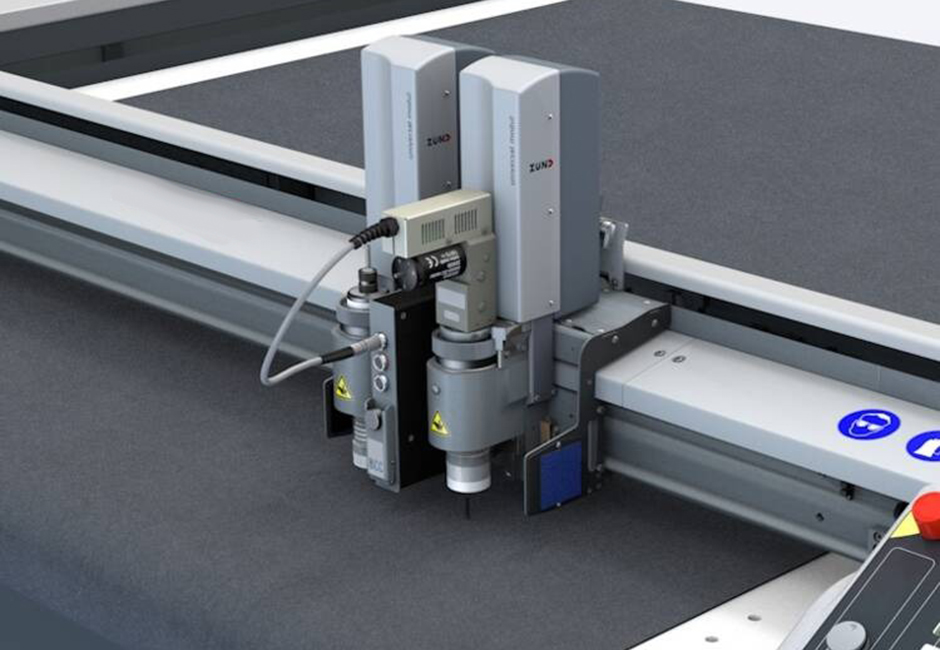

Precision Cutting with Advanced Technology

Crea Solution cutting systems integrate high-end electronic components and proprietary software to deliver outstanding performance and flawless cuts on any fabric. The combination of Italian mechanical engineering with state-of-the-art automation technologies results in powerful, lightweight machines capable of handling even the most complex productions with exceptional results.

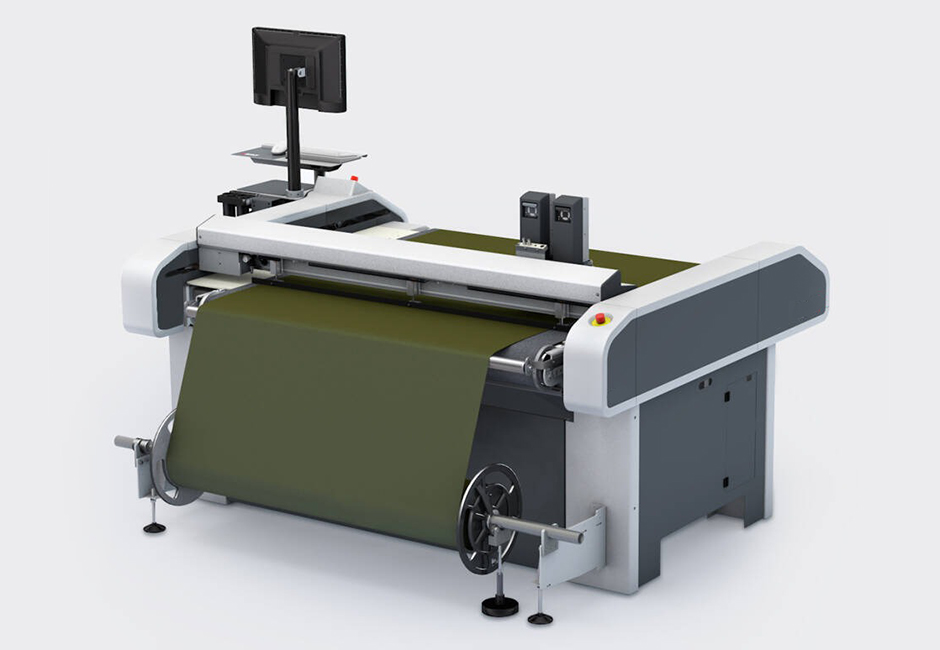

Perfect Spreading for Every Type of Fabric

Crea Solution spreading systems are designed to ensure precision and care for every material from fashion to technical fabrics. They spread fabric without mechanical stress, even at heights of up to 4 meters, and are compatible with all storage formats and methods. Their flexibility makes them ideal for every type of production, including Industry 4.0 environments.

Power and Precision for Any Production Challenge

Crea Solution cutting systems are engineered to efficiently handle even the most demanding tasks. Thanks to the quality of their components, optimized workflow, and seamless integration with ERP and CAD systems, they deliver fast, clean, and repeatable cuts reducing errors, waste, and production time.

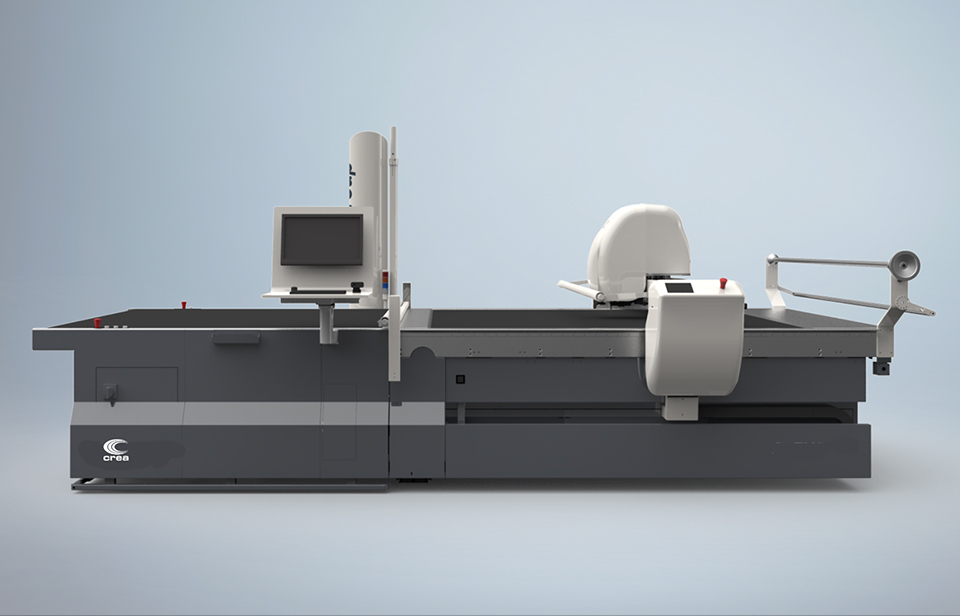

Continuous Production Without Interruptions

Crea Solution’s automatic leather cutting systems are designed for uninterrupted, continuous-cycle production. Loading, unloading, and cutting phases can occur simultaneously, supported by visual alerts and safety devices that guide the operator in real time. This ensures maximum efficiency without compromising workflow continuity.

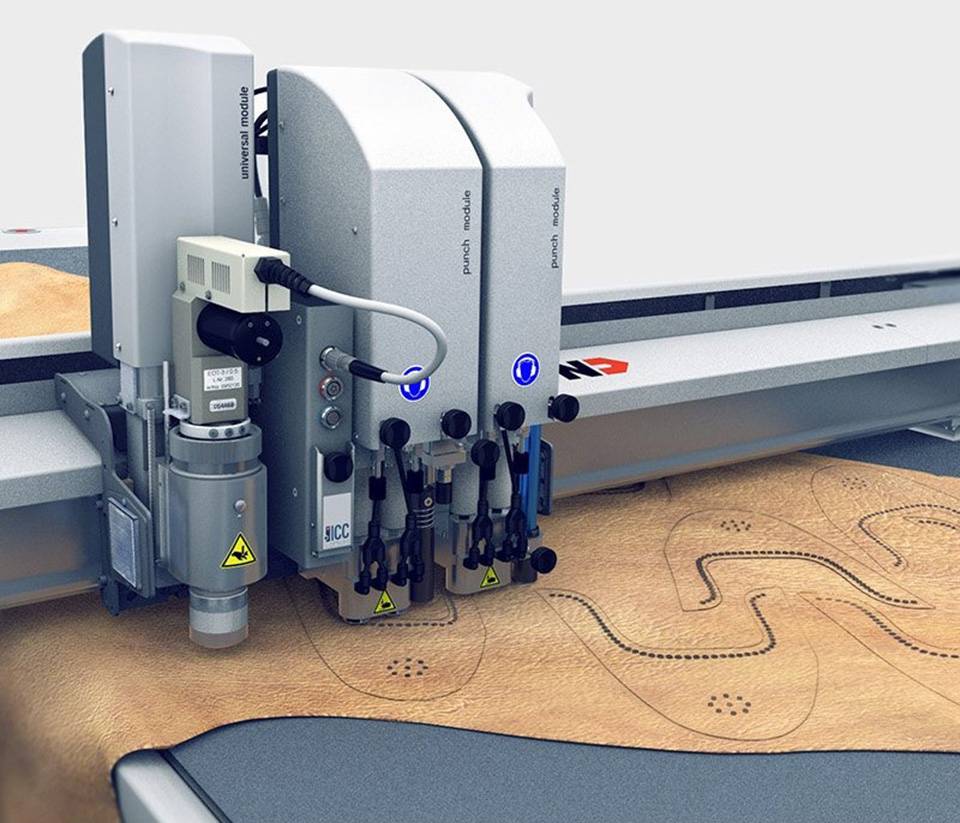

Tailor-Made Solutions for Any Production Context

Crea’s leather cutting systems adapt seamlessly to all production scales from prototypes to full-scale manufacturing. They offer extensive configurability, with a wide range of sizes, specialized tools, and smart modules for handling different materials. Thanks to their modular design, each system can be tailored to meet the specific needs of any business.

Smart Detection and Optimal Leather Utilization

Equipped with integrated artificial vision, Crea Solution machines automatically detect the usable areas of each leather hide, mapping them with precision. Nesting is optimized in real time even in multi-nesting mode and all data is stored in a centralized database, ensuring full traceability and consistency across future production lots.