Crea Solution 2025 – P.IVA 02483631202

All rights reserved

Alessandro Gherardi

Founded in 1997 in the Arezzo area of Italy, Gherardi quickly established itself as a standout in the world of men’s shirting. From the very beginning, the company demonstrated a strong ability to interpret and anticipate market trends, focusing on a refined and niche segment: custom-made shirts. This approach not only guarantees a perfect fit but also delivers a product with high aesthetic and stylistic value, expressing both elegance and artisanal quality.

With over twenty years of experience, Gherardi has built a solid reputation, collaborating with some of the world’s most prestigious luxury brands including Dior. This reflects not only the superior quality of its products but also the trust that high-end labels place in the company. Today, Gherardi operates two production facilities: one in Italy at the company’s headquarters with 85 employees, and another in Romania employing 70 people. Its annual production exceeds 500,000 shirts, highlighting the company’s ability to combine tradition with large-scale manufacturing.

One of Gherardi’s most significant challenges was optimizing production times, especially in the custom-made segment, which naturally demands more attention and longer lead times than standard production. Before adopting advanced technologies, the company was limited by partially manual processes, which negatively impacted speed and responsiveness to customer demands.

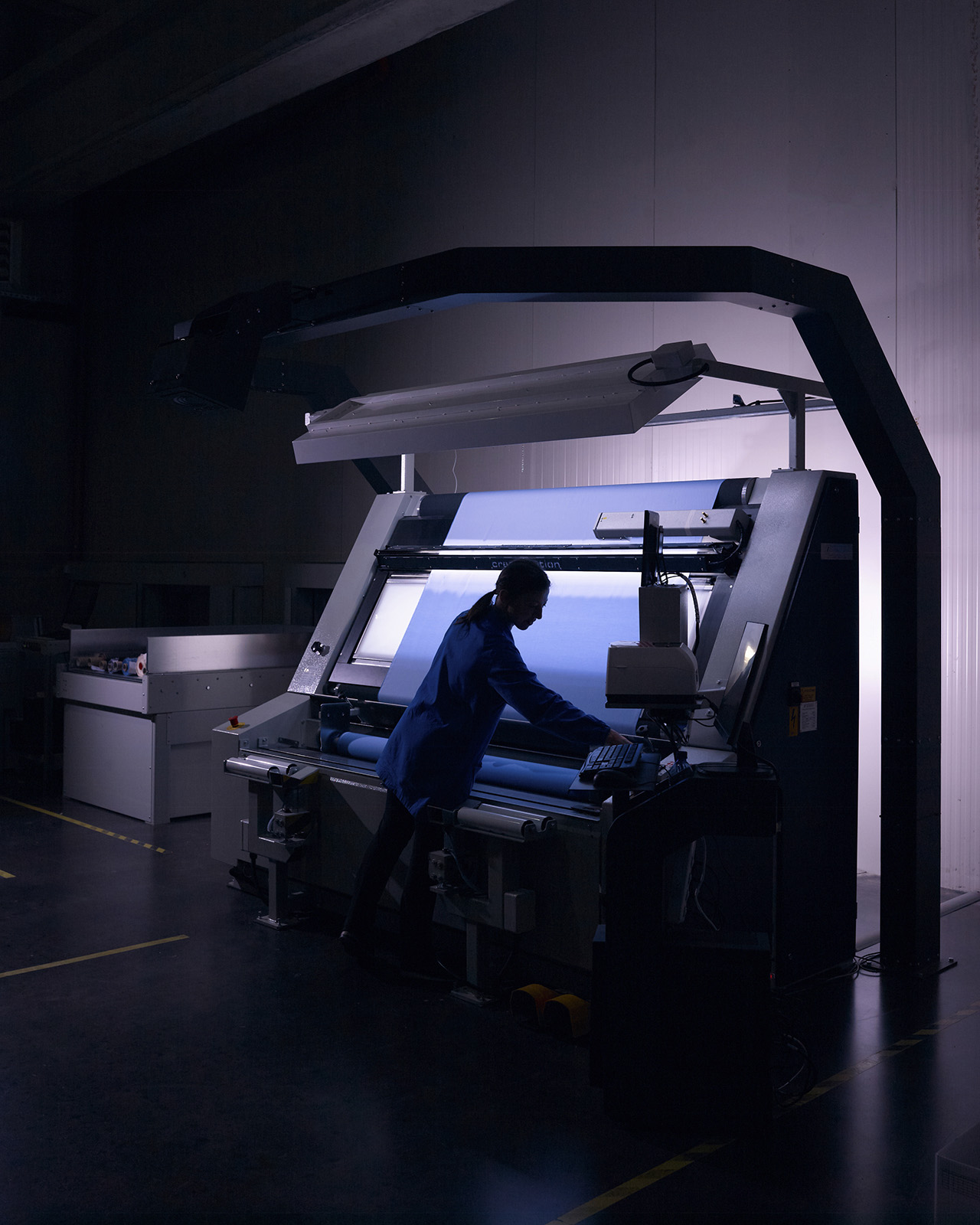

In search of an innovative solution, Gherardi decided to invest in a technological system integrated with IRIS, the artificial vision and cutting platform developed by Crea Solution. This technology marked a major turning point: thanks to its precision and automated cutting capabilities, Gherardi was able to reduce delivery times by approximately 35%, bringing the average turnaround down to just 15 business days. For clients requiring even faster service, the lead time can be shortened to only 5 days for an additional fee. This flexibility perfectly meets the needs of a market that increasingly demands speed without compromising quality.

One of the system’s key strengths is its ability to handle complex fabrics such as plaids, prints, and stripes that traditionally require skilled manual alignment to ensure precise pattern matching. Crea Solution’s system enables continuous-cycle cutting, significantly boosting productivity while reducing fabric waste and human error. Not only does this improve the sustainability of the production process, but it also lowers operational costs.

Today, Gherardi S.r.l. boasts an annual output of over 500,000 shirts, distributed across three main lines: 220,000 pieces under its own brands, 18,000 custom-made garments, and 275,000 units produced by the Gherardi Pro division, which serves top national and international fashion houses. This unique combination of volume and personalization is clear evidence of how technology and craftsmanship can successfully coexist in a demanding sector like luxury fashion.

Mr. Gherardi candidly shared the initial skepticism from his team regarding the new system:

“As with most changes, the operators were skeptical at first and didn’t believe the system would deliver on its promises. But after experiencing its full potential, they would never go back.”

This testimony highlights the importance of the human factor in adopting new technologies and how the right synergy between people and machines can lead to outstanding results.

In conclusion, the story of Gherardi is a powerful example of how technological innovation, paired with a deep-rooted tradition of quality and attention to detail, can transform an artisanal business into a major international player, able to meet the challenges of the modern market with efficiency and style.