Automatic Fabric Cutting in the Sportswear Industry

In the sportswear industry, production efficiency and customization have become two key elements for staying competitive in the global market. In this context, automatic fabric cutting represents a true technological revolution especially for brands working with patterns printed directly onto fabric. Thanks to the integration between advanced CAD solutions and the Adobe Suite, it is now possible to print, place, and cut patterns with unprecedented speed and precision.

The Evolution of Automatic Fabric Cutting: From Craftsmanship to Digitalization

Just a few years ago, producing customized sportswear involved a long and costly process. Today, thanks to automatic fabric cutting, the transition from a graphic file to a finished garment is smooth and direct. This is made possible by intelligent software that communicates directly with Adobe Illustrator, generating print ready files for production.

These digital tools allow users to:

- Import custom graphics;

- Automatically generate pattern placements;

- Create optimized files for fabric printing.

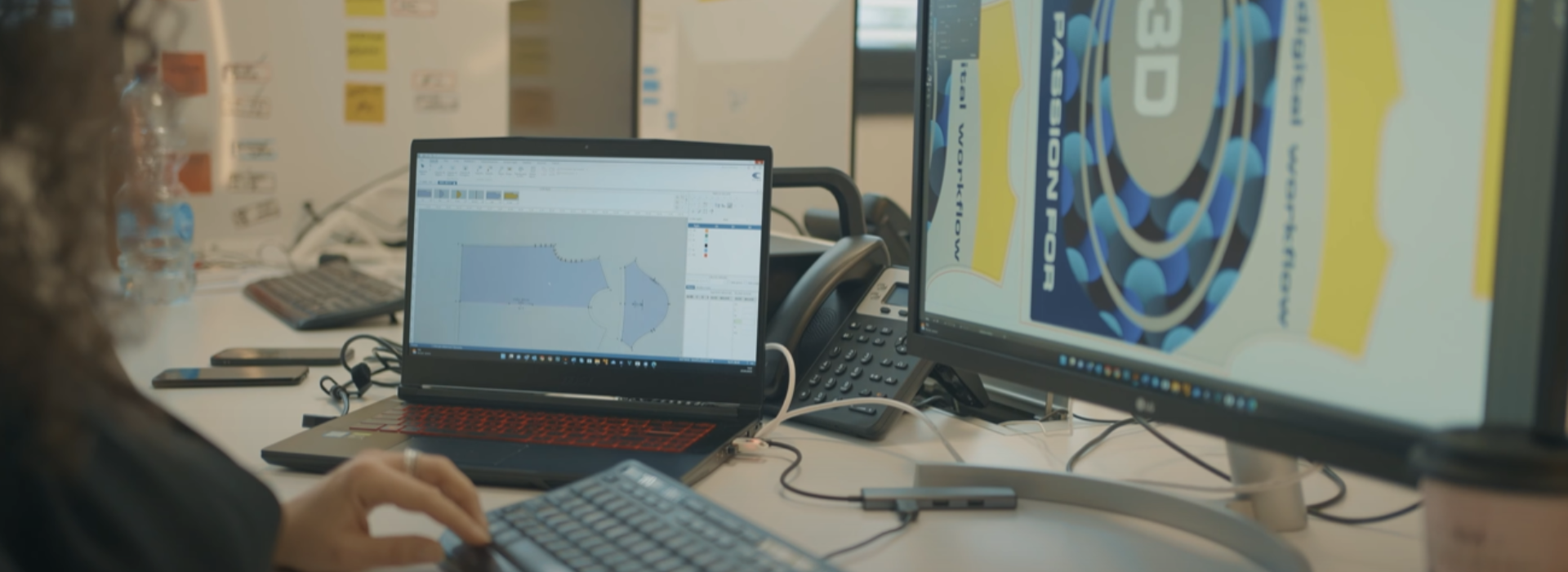

Automation begins at the design stage, with the ability to control every step of the process within a single interface.

Seamless Integration with the Adobe Suite

One of the most innovative aspects of this process including automatic fabric cutting is the native integration with the Adobe Suite. The advanced software enables pattern placement directly within Illustrator, maintaining full creative control. Graphics can be adapted in real time to garment shapes with perfect visual alignment.

Once the graphic design is complete, the system automatically exports files in a format compatible with textile printers. This drastically reduces both production time and the risk of errors.

Automatic Pattern Edge Detection

At the heart of the system is automatic contour detection. After the fabric is printed, the software reads and identifies the pattern edges with high precision even on complex graphics or advanced color effects.

This technology is essential to ensure cutting accuracy. No additional reference marks are needed the system processes images in real time and sends only the necessary data to the cutter.

Operator Control Remains Essential

Despite the high level of automation, the operator retains full control over the process. The software interface allows real-time adjustment of cutting parameters, monitoring of fabric alignment, and manual intervention when necessary.

This synergy between automation and human supervision makes automatic fabric cutting a powerful yet reliable tool ideal even for small production runs or prototypes.

Continuous Cutting: Uninterrupted Efficiency

One of the system’s most advanced features is continuous cutting. While the fabric is being scanned by the optical system, the cutter begins processing the patterns without pause. This constant workflow results in significant time savings and up to a 30% increase in productivity.

In the sportswear sector where collections change rapidly and deadlines are tight automatic fabric cutting with continuous flow offers a decisive competitive advantage.

Material Optimization and Waste Reduction

Another crucial benefit is material optimization. The automatic placement system minimizes fabric waste by efficiently distributing patterns. This not only lowers costs but also contributes to environmental sustainability aligning with the modern fashion market’s green goals.

A Strategic Investment for Sportswear Brands

Investing in an automatic fabric cutting system means faster production speeds, consistent quality over time, and unmatched flexibility in garment customization.

For sportswear brands focused on innovation, this technology is a strategic asset that allows them to:

- Launch capsule collections quickly;

- Offer a high level of personalization to customers;

- Improve efficiency across the entire production chain.

Automatic fabric cutting has radically transformed the way sportswear garments are produced, offering designers and companies new creative and operational possibilities. Integration with the Adobe Suite, automatic contour detection, operator control, and continuous cutting make this technology essential for anyone seeking quality, speed, and precision in a single system. If you work in the sportswear industry, now is the time to adopt automatic fabric cutting and take your production to the next level.