Innovation in the clothing sector: all the advantages of the CAD

The Italian clothing industry is a productive sector of enormous importance for the economy of the country. We are talking about numbers reaching 52.4 billion euros in 2015, 402.700 jobs and a trade balance of over 8.5 billion euros. The sector traditionally generates a surplus of the trade balance preceded only by that of mechanics, as reported by “Il Fatto Quotidiano” in this article: “Moda e tessile, analisi di un settore in crescita. E l’Italia resta un’eccellenza.“.

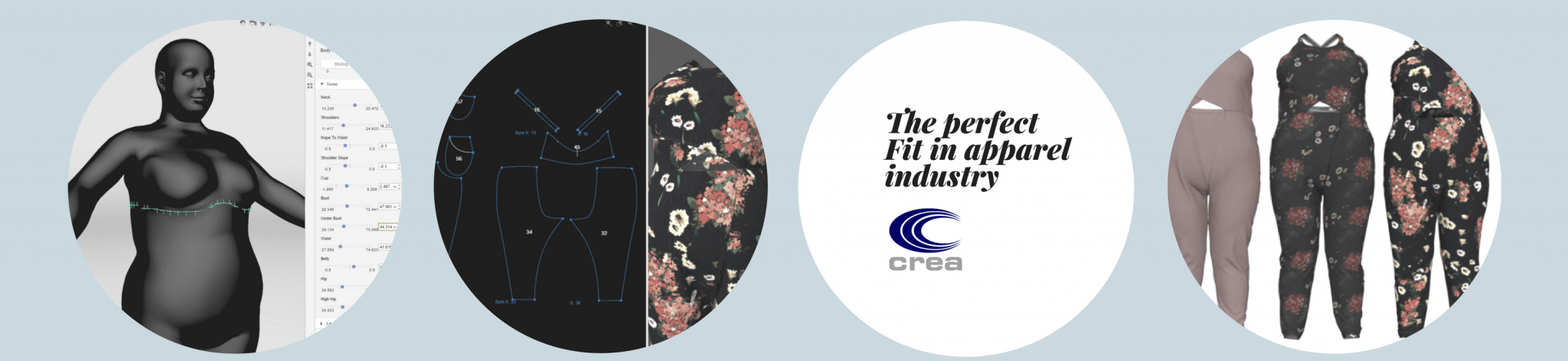

The system owes its competitiveness to investments in innovation, which allow to digitize the creative process and production models. 2D CAD and 3D CAD for clothing are now necessary tools to work quickly and extremely accurately, as well as to speed up processes that once took days of work.

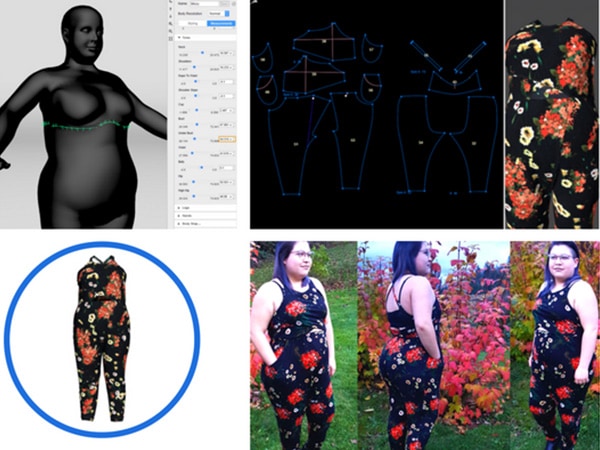

The fitting in the clothing industry is one of the key parameters for assessing the quality of the garment sold. To aspire to perfect fitting it is necessary to create prototypes, to make the fitting with real models, and to separate the models until reaching the desired result. To overcome these processes that today require time, specialized figures and involve costs (a prototype costs on average from 300 euros to over 1000 euros) the most complete companies use 2D CAD and 3D CAD technologies for clothing that reduce drastically the time-to-market and the costs.

Smart size grading.

In order to guarantee a suitable fit for the consumer target by accelerating the process it is important to have the possibility to automatically grade the sizes of the clothing models previously created at CAD. Expander ™, the module for the size grading of Create™, allows you to individually define the values for buttons, lines, folds, pleats and any other element within the model. It simplifies the management of the corners, the notches and the development of the zones, makes immediate operations such as changing the size plan, accelerating repetitive actions. Each size is defined as a piece in its own right, allowing you to define its shape exactly.

Controlling and physically prototyping all the different sizes of a garment during the product development process takes a long time and this step is often skipped. Thanks to the 3D technology it is possible to control the sizes by creating 3D prototypes in a fast and precise way, without having to create all the physical prototypes. Another problem related to sizes is the positioning of the graphics in all the dimensions of the garment, 3D CAD for apparel allow you to place the graphics on the 3D virtual garment, resize and adjust the size and position on more sizes, having so complete control over how your graphics are displayed on garments.