All-over fabrics: how to match the motifs in the different parts of the patterns

The autumn winter 2021/2022 fabric trends still see repeated prints and motifs, all-overs, checks, stripes, numbers, repeated logos, prints and nesting.

The production of garments with printed, all-over, repeat motifs, checks or stripes takes much more time and energy, especially when it comes to high fashion. In particular, the nesting of the patterns on fabrics with repeated motifs (often high fashion logos, numbers or letters) is often done manually to ensure the perfect match of the parts of the pattern, once packaged. The largest fashion companies in fact create the garments with extreme precision, the attention to detail starts from the nesting of the patterns on the fabric to the cut itself. The result is always a very high quality product which can be seen not only from the design and finish of the raw materials, but also from the arrangement of the repeated motifs in the final model.

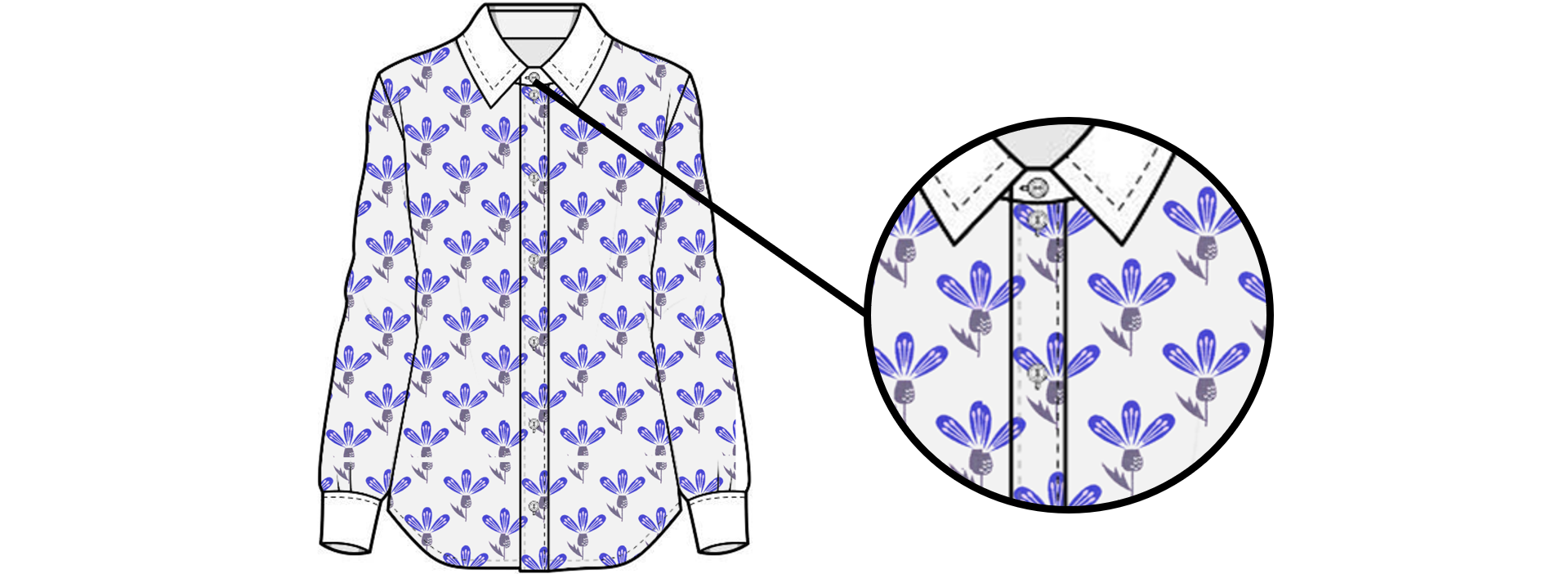

In the image below you can see the quality in the details that great fashion brands are looking for, the nesting is so scrupulously performed as to ensure the perfect match between 3 different parts of the model (front, left, right and buttons). The purple flower is kept in its shape and the all-over is not interrupted.

In order to obtain results of this kind, it is possible to perform the work entirely by hand or use artificial intelligence to perform this type of nesting and cutting in a totally automatic way. It is not a question of purchasing a simple automatic cut, but an integrated system that embraces various business areas and, thanks to a vision system and powerful algorithms, acts and makes decisions as if it were a human brain.

More and more customers (high fashion brands, manufacturers and subcontractors) are adopting the patented Crea Solution systems to automate this delicate process.

Let’s see how the system works

Survey Fabric All-over

The SURVEY FABRIC ALLOVER system is able to detect repeated motifs, known points (letters, logos, drawings, numbers, etc.), linear or diagonal of the fabric, even tone-on-tone and infinitely small. The process starts from a nominal nesting that is done in such a way as to match the motifs of the fabric exactly in the various parts of the model. The nesting will then be reproduced by the automatic cutting machine but without the possibility of being able to intercept the position of the fabric motifs it is impossible to perform a perfect match. Through a sophisticated vision system, the system performs a complete and detailed scan of the fabric, identifying the motifs even diagonally and tone-on-tone, as well as the folds and any defects in the fabric (linear or punctate).

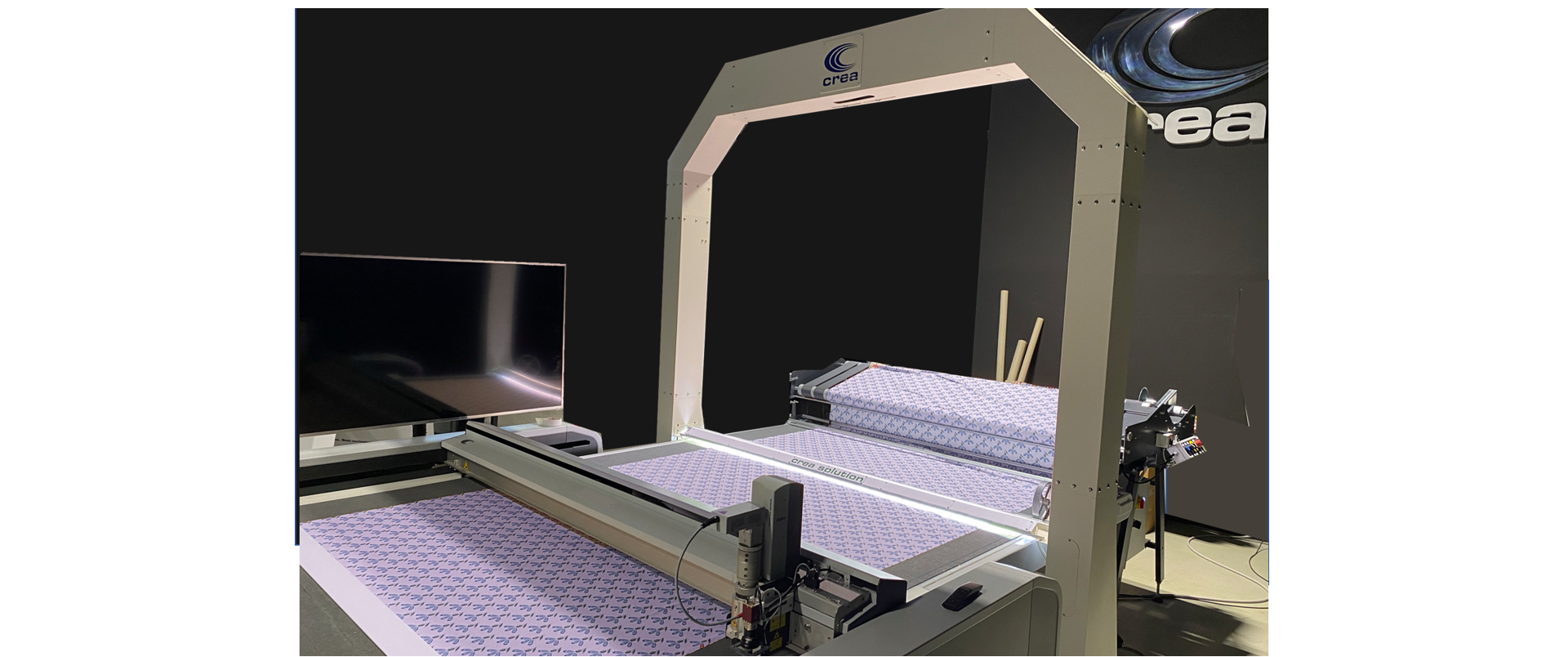

Single Ply cutter with Crea Solution Vision System

While the fabric advances on the cutting mat and is viewed by the cameras, the system compares the nesting to be cut with the real conditions of the fabric by adapting or reworking the nesting to create a perfect match between the models and the motif of the fabric itself, the cut parts are then ready to be sewn.