3D Apparel Clothing, what really makes the difference?

One of the biggest costs in the fashion industry is the prototyping of garments. There are companies that turn to services or prototype internally, in both cases it is a big effort in terms of time to market and costs. This simply happens because for each garment made it is necessary on average 6 prototypes, with the corresponding phases of adjustments. Assuming on average the production of 300 garments a year by a fashion company it is clear that the prototypes are made and then discharged are 1800. In addition to the strong waste of material there is the need to have highly specialized figures for sewing and ironing of the prototypes themselves, as well as fitting models.

We have already discussed in the previous articles how 3D apparel clothing technologies have revolutionized business processes, generating such realistic and perfect fitting that they can drastically reduce the prototyping phase. Thus, ensuring great business efficiencies and reduced time to market. But what really makes the difference in a 3D apparel for clothing software? and what are the features that allow the complete interaction of this technology with business processes?

The possibility to have realistic renderings with folds.

The folds of the fabric are present in many of the garments we wear every day. Collars or lapels are the most common clothing attributes for a folding app, but cuffs, hems and other casual neckline designs can be folded. The construction and execution of the fold has a great visual impact on the design of the garment. The collars of the shirts have a very rigid fold, while the turtlenecks and the polo collar have a casual and soft fold. Each of these folds corresponds to the design and manufacture of the garment.

A 3D apparel clothing software for performing clothing in this area should at least offer 3 options to create the fold finish to match your garment.

- Soft Fold: a soft line will produce a very casual looking result. It can be used on polo shirts, jackets or sweatshirts with thicker or softer fabric, or buttoned shirts with less structure (Hawaiian shirts).

- Sharp Fold: the visual result of the sharp crease will have a fresh and ironed appearance. This fold is normally used for formal dress shirts and full jackets.

- Normal Fold: the normal fold line is very versatile and will produce an intentional fold without the formality of the sharp fold. This type of fold can be used on casual, sporting and formal garments.

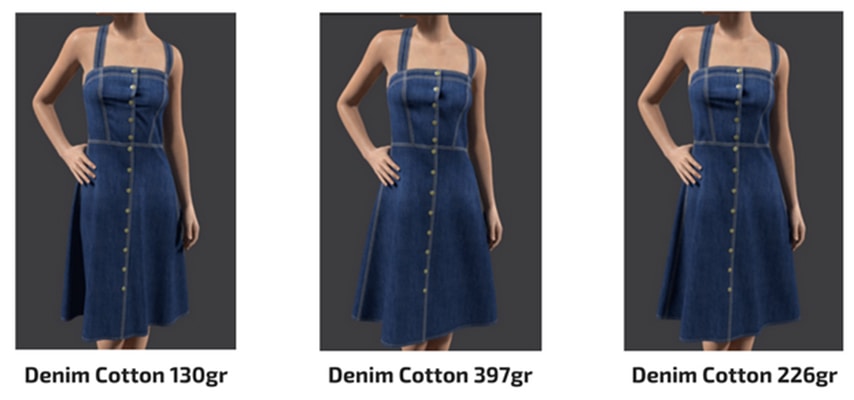

A device able to import fabrics analyzing their real data.

One of the perplexities of fashion designers with respect to 3D CAD concerns the acquisition of the characteristics of their fabrics within the 3D software system. Thanks to a special tool it is possible to analyse the thickness, weight, stretch and bending of each fabric and automatically load the values in VStitcher or other similar 3D software programs. A 3D for apparel clothing should have a similar device that, with a supplied fabric database, will show the garment in every variant.

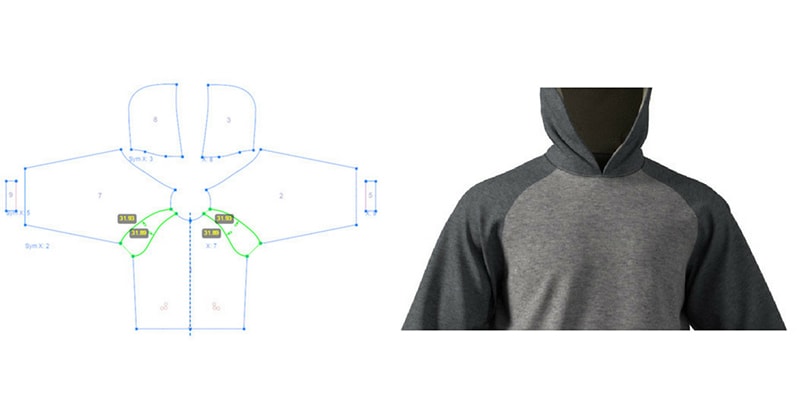

Correct simulation of sewing information.

Patterns can often have small differences in the lengths of the edges and in the shape of the edges from the front to the back or from the left to the right. These small differences can have a big impact on fitting. For example, in a raglan sleeve, it is essential to perform the seams correctly or the seam of the armhole will show an extra fullness. Because the differences are very small, errors can sometimes occur during production. Using 3D software for apparel clothing, you can verify that the sewing instructions are correct before running samples. For example, take this sweatshirt with raglan sleeves. In the first 3D simulation in VStitcher, the sleeves are sewn correctly:

In this second simulation, you can clearly see the extra fullness in the front caused by the wrong seam.

Representation of the folded garment.

Another useful feature of 3D for clothing is the ability to create folded shirt displays. To help refine the design process, brands can easily create a 3D simulation of a folded shirt or shirt for an accurate representation of the garment when it is marketed and sold. It is possible to work directly on the design of the folded shirt to create infinite styles by changing colors, fabrics, stitching, buttons, yokes, collars and more. It is also possible to add presentation elements such as stickers, tags and plastic collars. Seeing the folded t-shirt offers another perspective for the design process.