Xacus : quality, research and innovation for a top brand made in Italy.

Xacus is a world leader in the men’s shirt sector with a distinguished international presence. Remaining firmly rooted in its tailoring tradition, the company has retained and enhanced its distinct product characteristics to create a brand legacy synonymous with unique style, exclusive details, premium materials and precision accuracy throughout each phase of development from the initial design concept to final production.

“Since 1956, the basic principles of the Xacus philosophy have been quality and innovation.”

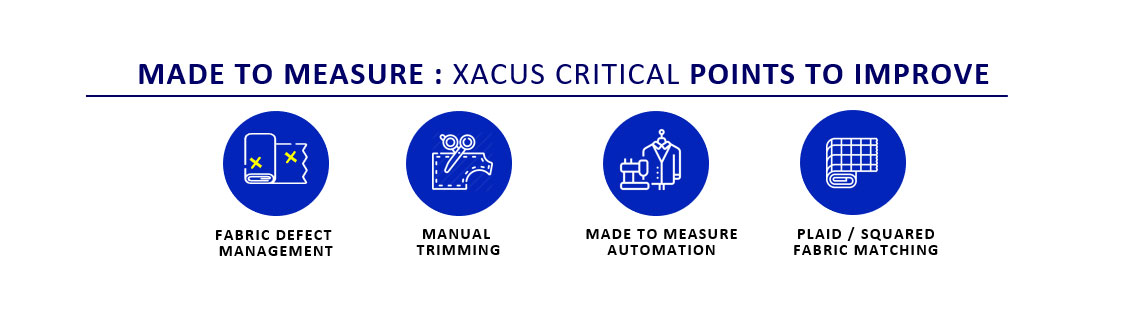

Creating efficiencies in the whole production flow as well as reducing fabric consumption are only two of the main goals for Xacus to be achieved. The major critical points regarding the consumption of the fabric lie in the quality control and in the plaid and striped pattern match. Sometime happens that on a long piece of fabric there are some defect that could compromise the quality of the final shirt. In the workflow Xacus used to have before adopting the vision system by Crea Solution this problem caused waste of material and time. They used to cut the fabric with defects and have a quality check of every piece afterwards. The same problem was raised by the client even for the plaid/striped shirts : to get the perfect match the pattern pieces were cut with an edge of extra fabric so as to be manually trimmed. In both cases there ware a significant waste of fabric that the company needed to control and reduce.

|

|

|

The made to measure process adopted by Xacus is a complete automation of the mtm pattern creation. Once the measurements of the final client are inserted in the portal the pattern is created and modified automatically with no need of pattern makers. The same happens for the automatic nesting afterword, on solid, plaid or striped fabrics. In this way is possible to avoid errors and automatize the whole made to measure process.

“From now the nesting will be made only on the fabric suitable for being cut and sewed, with consistent save of material and time”

|

|

|

The new MTM workflow

To overcome the main critical issues and create efficiency in the fabric management Xacus adopted the Crea Solution automated system for fabric vision and cut. The artificial vision, along with AI Algorithms, allows to have a complete and precise fabric reading in order to detect every single defect or fold, doing that the system can automatically change the nesting (or patterns) to avoid the defective parts and optimize at most the use of fabric. In this way the system is capable to make a clean final cut and the pieces are ready to be sewed with no need of hand made trimming.

How to be the most productive made to measure shirt company in 2020

• RISPARMIARE TESSUTO E AUMENTARE I MARGINI: Now Xacus is able to exploit at 100% the fabric without manual labor. The algorithm of automatic nesting along with the artificial vision adjust the marker in order to nest only in the good parts of the fabric.

• RISPARMIARE TESSUTO E AUMENTARE I MARGINI: No need for manual labor to create or edit MTM patterns nor for spreading the fabric, detecting detects, nest the pieces and cut. This automated process improved the whole workflow reducing drastically the production time.

• RISPARMIARE TESSUTO E AUMENTARE I MARGINI: The automation leaves no space for errors and guarantees high quality standard to every shirt ever produced. The high quality is evident even in the perfect matching of squared and striped shirts.