3D Fashion Design Software: all the advantages of our 3D CAD

In the fashion industry, wearability is essential for every garment and therefore for every pattern. It is an aspect that must be taken care of with the utmost care and precision to prevent the items from being too tight, thus limiting the movements of the wearer. One of the biggest challenges for companies in the fashion industry is to ensure that the fit of a garment is as suitable as possible for the target customers.

To ensure maximum wearability, it is necessary to make several samples and separate them during the fitting phase up to the pattern which will then be industrialized. Communication between the pattern making and design department has always been one of the biggest challenges for multinational companies and large companies. Often the style offices are located in a completely different time zone compared to the production one and the decision making in the approval phases of the garment has a time often dilated.

The digitalisation of creative processes through 3D fashion software can overcome all these problems. With the advent of 3D fashion design in clothing design, a clothing sample can be created from scratch almost instantly, allowing design teams to make decisions about their marketing without having to produce a prototype and thus significantly reduce time-to-market.

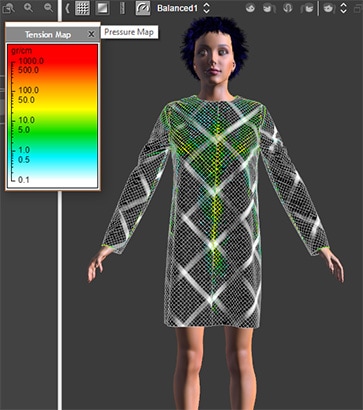

When you rely on 3D for design, the key thing is to make sure that the 3D prototype replaces 100% the physical one, whether draped, with a heavy fabric, with seams, finishes and accessories. An important aspect to obtain a realistic fitting is therefore that of the fabric, which must faithfully represent all the characteristics and physical properties, such as the ability to bend under its own weight and elasticity along the x and y directions.

Furthermore, fineness, transparency, shading, lucidity and reflection as well as the pressure on the body and the tension of the moving fabric are information that allow a much more realistic drapery during the rendering of the finished garment. It is exactly in these details that 3D fashion design accelerates decision-making processes within fashion companies.

Here are some features that distinguish a 3D CAD able to replace the physical prototyping of garments:

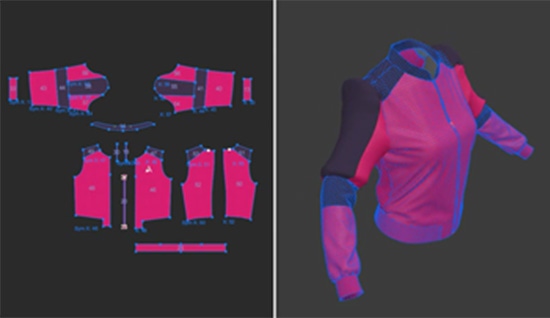

- REAL TO LIFE 3D FASHION PROTOTYPING

Or the ability to create or modify patterns and translate them into a realistic 3D prototype that shows endless variations from the physical properties of the fabric to the visualization of the material, stitching, pockets, layers, padding, folds, rigid 3D accessories and finishes.

- PHYSICAL PROPERTIES OF THE FABRICS

The ability to visualize the way in which any fabric folds and falls on a real human body with an incredible 3D fabric draping technology. You can measure the exact physical properties of any fabric using a proprietary digital sensor that connects directly to the VStitcher.

- AVATAR IN MOTION

To simulate the pressure and the tension of the garment you have an infinite number of avatars from any source to improve realism and precision. You can also view moving patterns and capture complex poses with smoother transitions.

- INTEGRATION WITH ADOBE ILLUSTRATOR

Work simultaneously with image, vector, and pattern design software in a variety of 2D and 3D file formats, through a continuous runtime integration that constantly updates both files.

- ANALYSIS OF THE AUTOMATIC TEXTILE PROPERTIES

The Fabric Analyzer can analyze any fabric for any visualization application including footwear and bags. Fabric Analyzer allows you to determine the thickness, stretching and folding properties of the fabric and to automatically load the values in VStitcher or other similar 3D software programs.

- DESIGN ON DIFFERENT SIZES

Have you already got used to the Design in Sizes tool? This is one of the tools developed specifically for all clothing designers who struggled to keep costs down while perfecting the scale and positioning of the graphics in all sizes. The tool allows you to position the graphics on the 3D virtual garment, then resize and adjust the size and position on multiple dimensions in a set. Design in Sizes is the 3D fashion tool that gives complete control over how your graphics are displayed on garments of all sizes.

- TECH PACK

Instantly generate detailed specifications ready for the PLM software to produce the 3D leader. Each downstream team member receives exactly the information he needs, including materials, finishes, workmanship, pattern prints and more.

A look at the future

Over time, we will see that companies will no longer depend on the footsteps of the big names in the fashion industry. Each brand will have access to advanced 3D tools to become trendsetters. The collections will no longer take several months to be produced and, thanks to 3D digitization, the entire workflow from start to finish will be reduced to a few days, ensuring that every new design is current and relevant. Realistic 3D digital clothing displayed on websites and catalogues will be so accurate that the customer will not realize that they have not yet been produced and that the brands will fill each order as it is placed. With intelligent manufacturing options, small local factories will appear to fill orders faster and more efficiently, significantly reducing waste.